Screw Tightening Moments

Tightening Moments For Lineer Guideways and Carriages

Warnings

• Under large loads, screw connections can not prevent sideways slippings of guideeways and carriages

• In case of large loads, , structural precations should be applied for the slipping of guideways and carriages.

• Should be always an attention on screw manufacturer.

• Suitable material’s resistance should be provided for the sturucture of connection.

• Tighten your screws with small heads in according to DIN 6912 by the class of 8.8.

Tightening Moments For Mounting Screws DIN 912/ISO 4762 (µ=0.125)

If mounting screws are greased with MoS2-containing grease and tightened using a torque wrench ;there will be obtained a smoother pre-stressing force that significantly increases accuracy in the region.

Warnings

• Especially in case of using MoS2-containig grease, friction coefficient (µ) can be reduced by half.

• There for moments can be reduced.

• Screws are surrounded with adhesive despite pre-stressing loses are expected.

Tightening Moments for Front Plates and Additional Wipers

Maximum tightening moments is shown in the table below for mounting screws on additional wipers and front plates.

Warnings

• Screws are surrounded with chemical screw adhesive. That adhesive strength can be reduced by the repeated screwdriving and putting screws out, there for it may cause the screws to loosen.

• Please do not use mounting screws repeatly.

Lubrication Amounts For Initial Lubrication

Application Process

• Lubrication amounts for MONORAIL MR and also AMSA 3B, AMSD 3B, AMSA 3L, AMSABS 3A.

• Lubrication amounts for MONORAIL BM and also AMSA 4A, AMSD 4A, BZ.

Notes

• Schneeberger; recommends KP2K grease which compatible with DIN 51825 or GP00N/GP000N grease which has low viscosity and compatible with DIN 51826.

• Defined lubrication amounts are obtained for both grease and liquid grease.

• During lubrication of carriage, move the carriage 3 times by the lenght of carriage.

• If carriage has 2 lubrication connections, defined lubrication amount might be divided to the connections.

• In case of using GP000N, pay attention to the axis mounting position.

Lubrication with Oil:

Notes

• Schneeberger recommends CLP (DIN 51517) or HLP (DIN 51517) as mineral oil. (viscosity ISO VG32…ISO VG100(DIN 51519) )

• Bearing part’s oils can be used until CGLP ISO VG220.

General Information For Lubrication

• To the moving carriage, total amount of oil can be added to have only one vibration movement at the same time or repeatedly fast vibrations.

• In case of vertical installation of carriage, lubrication connection should be the top of front plate.

• Per carriage lubrication can be divided by the specified amount to the dual connections.

• During lubrication of carriage, move the carriage 3 times by the lenght of carriage.

• Pay attention to installation axis. ( Seperated lubrication)

• Required working strokes should be cleaned before and after lubrication.

Cable Bending Radius

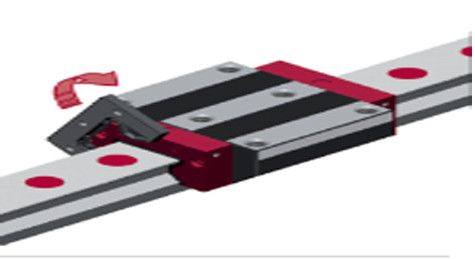

GUIDEWAY MAPPING INFORMATION

The lenght of a single piece of SCHNEEBERGER MONORAIL guideway is 6 meters.

Longer lengths can be made by combining two or more rails.

The guideways are joined to the forehead without any spaces.

The multi-piece guideways are marked with a number on the stepped connections and these numbers are matched to be identical.

The numbering of the guideway connections and the assembly are shown according to the setting numbers.

Please install the guideways to match the numbers.

The guide rail with reference number 1 or the reference link rail 1 are set as reference rails.

When installing the multi-part guide rails without the mounting surface of the machine bed, align the guide rail supports using a fixing bridge.

During installiation, with placing the surface by the machine side, place the refences guideways as placement faces to be fit in their location..In both cases, note that the guideways are assembled without a gap.