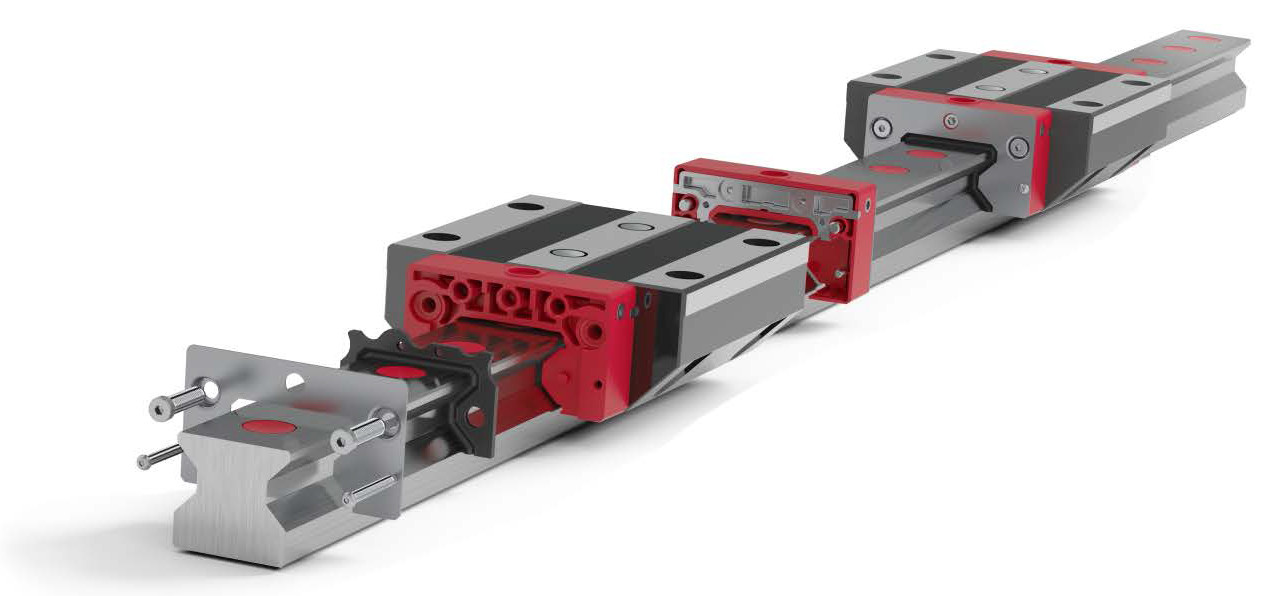

SCHNEEBERGER MONORAIL MR Profiled Linear Roller Guideways

High rigidity, great dynamic and static load carrying capacity, outstanding running smoothness and the total enclosure of the carriage are the main features of the MONORAIL guideway. These properties result in higher machining rates while enhancing geometrical accuracy and surface quality of the machined workpieces. Our highly rigid MONORAIL provides improved vibration behavior, smaller vibration amplitudes and thus extends tool life.

High rigidity, great dynamic and static load carrying capacity, outstanding running smoothness and the total enclosure of the carriage are the main features of the MONORAIL guideway. These properties result in higher machining rates while enhancing geometrical accuracy and surface quality of the machined workpieces. Our highly rigid MONORAIL provides improved vibration behavior, smaller vibration amplitudes and thus extends tool life.

SCHNEEBERGER has systematically applied its many years of experience in the design, production and use of roller-type anti-friction guideways in the development of the MONORAIL. Consequently the MONORAIL MR is a cost-effective anti-friction guideway which meets the challenge presented by modern machine design.

New Profiled Guideways shine through 4 «S»

MONORAIL MR – Next Carriage Generation 4 reasons to love the new SCHNEEBERGER MONORAIL MR 4S series: An optimized lubrication system, ease of maintenance, shock resistant, and dirt repellent.

4 reasons to love the new SCHNEEBERGER MONORAIL MR 4S series: An optimized lubrication system, ease of maintenance, shock resistant, and dirt repellent.

• Serviceability – compatibility, exchange of cross wipers

• Supply of lubricant – pressure-tight lubrication channels

• Shock resistance – body optimized for rigidity

• Sturdiness – robust and well-secured front plates

Technical Measure

Advantages

• Four different accuracy classes

• Three different preload classes

• Special set processing through system grinding and paired rails supporting high accurate machines

• Carriage and rail types for attachment from above and from below

• Single piece rail length up to 6 m

• Final dry grinding process of carriage mechanical interface, no change of preload during assembly and operation

• Superior rail straightness as a result of advanced grinding and straightening technology

• Wide scope of accessoires and options

• Different coatings for corrosion protection

• Through-hardened carriages for long-lasting product properties, no loss of preload for constant machine execution

• Optimized path geometries for rollers and transitions for quiet, smooth operation

• Low drag wipers to protect rollers against the environment-corrosion resistance with specially thin dense chrome-plating optional

• Stainless steel cover-strip

• Various hole plug options for long lifespan of wipers

Features

• O--geometry

• O--geometry

• Through-hardened carriages

• Complete sealing

• Lubrication connections

• Exchangeability

• Running smoothness

• Rigidity

• Load carrying capacity

- A SERİSİ STANDART ARABA 4S.rar DOWNLOAD

- B SERİSİ UZUN ARABA 4S.rar DOWNLOAD

- C SERİSİ DAR YÜKSEK ARABA 4S.rar DOWNLOAD

- D SERİSİ DAR YÜKSEK UZUN ARABA 4S.rar DOWNLOAD

- E SERİSİ YANDAN BAĞLANTILI ARABA 4S.rar DOWNLOAD

- F SERİSİ DAR ARABA 4S.rar DOWNLOAD

- G SERİSİ DAR UZUN ARABA 4S.rar DOWNLOAD